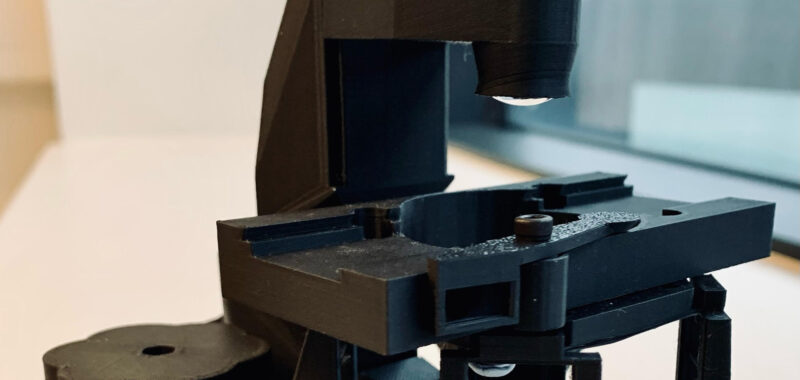

Researchers have designed and built the world’s first microscope made entirely from 3D-printed parts. And because the open-source plans are already available online, almost anyone can assemble their own for barely $60.

A few years ago, researchers at the University of Bath and University of Cambridge started the OpenFlexure project offering open-source blueprints for 3D-printed microscopes. With its core development group now based at the University of Glasgow, OpenFlexure microscopes have been assembled in over 50 countries around the world, as well as at laboratories in Antarctica. While much cheaper than standard equipment, there was a caveat: a microscope’s specially crafted glass lenses often cost hundreds of dollars, putting the tools out of many people’s price range. Recently, however, a team at the University of Strathclyde developed a workaround they say both lowers the OpenFlexure design’s total cost, and makes it the first completely 3D-printed microscope.

“Optical microscopy has long been a cornerstone of scientific discovery, driving advances across diverse disciplines from biology and healthcare to materials science, petrochemistry and geology,” the team writes in a preprint study for the journal Biology. “However… [the OpenFlexure microscope’s] dependence on commercial optical components limits the accessibility and adaptability that a fully 3D printed microscope could achieve.”

To solve this issue, researchers built off recent advancements in optical-quality, 3D-printed lenses. They then programmed a Mars 3 Pro 3D printer to use a photopolymerising clear resin to build a lens using the same parameters as an Edmund Optics 12.7 mm diameter plano-convex lens with a 35 mm focal length. The microscope is completely functional once printed and assembled as is, but the designers took their project a step further by installing a store-bought camera and light source controlled using a Raspberry Pi computer processor. But even with the additional components, the entire microscope cost around $60 and took less than three hours to build.

The first samples examined using their new equipment included a blood smear and a thin section harvested from a mouse kidney. The 6.6 lbs microscope’s magnification provided an imaging field view of 1.7 mm with a single cell spatial resolution of around 5 micrometers. Images provided in the study clearly depict individual blood cells, renal tubules, and other sub-cellular anatomical details.

“[C]onsider the commercial alternative, where a research or clinical grade microscope can be upward of [$18,200] and, in the case of field diagnostics in low-resource settings, presents issues surrounding the availability of instrument servicing and replacement optics or optomechanical parts,” researchers explain in the study.

Future iterations aren’t only stuck with this particular lens—according to the designers, alternative magnifications and apertures are also possible, and will hopefully be explored for different versions of 3D-printed microscopes.